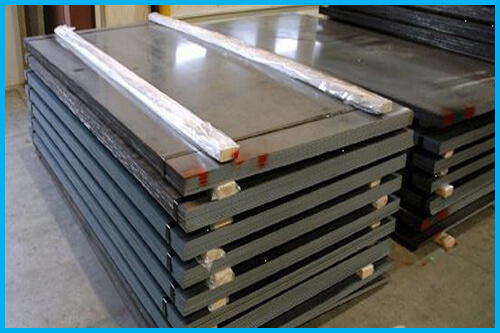

Looking for a cost-effective solution to extend equipment life and reduce downtime in abrasive environments? Wear Plates are engineered to protect critical components from constant abrasion, impact, and material flow. Buyers across industries rely on Wear Plates because they deliver longer service life, predictable performance, and significant savings in maintenance and replacement costs.

Looking for a cost-effective solution to extend equipment life and reduce downtime in abrasive environments? Wear Plates are engineered to protect critical components from constant abrasion, impact, and material flow. Buyers across industries rely on Wear Plates because they deliver longer service life, predictable performance, and significant savings in maintenance and replacement costs.

Why Buyers Prefer Wear Plates

Buyers today focus on materials that improve productivity and lower total cost of ownership. Wear-resistant steel plates meet these expectations by combining high hardness with controlled toughness. As a result, they perform exceptionally well in environments where standard structural steel fails prematurely.

Moreover, Wear Plates allow buyers to design lighter and more efficient equipment. By using abrasion-resistant material only where wear occurs, procurement teams optimize material usage and control budgets. Consequently, operations run longer with fewer shutdowns.

Key buyer-oriented advantages include:

-

High resistance to sliding and impact abrasion

-

Extended equipment service life

-

Reduced maintenance and downtime

-

Lower replacement and operational costs

-

Consistent performance in harsh conditions

Because of these benefits, OEMs, plant operators, and EPC contractors increasingly specify wear-resistant steel for critical applications.

Technical Specifications of Wear Plates

To support confident sourcing decisions, buyers need clear technical information. Below is a generalized overview covering commonly used wear plate grades.

Chemical Composition (Typical %)

Wear plates typically feature a low-to-medium carbon steel base with alloying elements for enhanced hardness and toughness:

-

Carbon (C): 0.12 – 0.32

-

Manganese (Mn): 1.00 – 1.60

-

Silicon (Si): 0.20 – 0.50

-

Chromium (Cr): 0.40 – 1.20

-

Nickel (Ni): 0.25 – 0.80

-

Molybdenum (Mo): 0.15 – 0.45

-

Boron (B): Max 0.005

This alloy design ensures uniform hardness and reliable wear resistance.

Mechanical Properties

Mechanical properties vary by grade (e.g., 400, 450, 500 HB), but typical values include:

-

Hardness: 360 – 550 HBW

-

Yield Strength: ≥ 900 MPa

-

Tensile Strength: 1100 – 1700 MPa

-

Elongation: Approx. 8–14%

These properties allow wear-resistant plates to withstand continuous abrasion and impact loading.

Available Forms

-

Abrasion-resistant plates and sheets

-

Cut-to-size wear plates

-

Profiles and fabricated wear parts (as per drawings)

Applications

Wear plates are widely used across multiple industries, including:

-

Mining liners, crushers, and chutes

-

Excavator buckets and dump truck bodies

-

Cement, coal, and aggregate handling systems

-

Recycling and quarrying equipment

-

Construction and earthmoving machinery

International Standards & Equivalents

Wear-resistant plates align with several international standards and equivalents, ensuring acceptance across global projects:

-

UNS: Abrasion-Resistant Steel Categories (varies by grade)

-

ASTM: ASTM A514 / AR400, AR450, AR500

-

ASME: ASME SA 514

-

DIN / EN: EN 10051, EN 10204 (related wear and structural standards)

These standards help buyers integrate wear plate materials into international specifications with confidence.

Regional Buyer Demand Focus

-

India

-

Strong demand from mining, cement, and infrastructure sectors

-

-

Germany

-

Preferred for precision wear components and heavy engineering

-

-

UK

-

Widely used in recycling, quarrying, and bulk handling plants

-

-

UAE

-

High usage in construction, ports, and material transfer systems

-

Why Partner with Vandan Steel & Engg.co

Selecting the right supplier is critical for consistent quality and reliable project execution. Buyers choose Vandan Steel & Engg.co because we combine product expertise with dependable service.

-

Mill Test Certificates (MTCs) for complete traceability

-

Flexible MOQs to support projects and stockist needs

-

Efficient domestic and international logistics solutions

-

Technical support for grade selection and application guidance

-

Consistent quality with on-time delivery commitments

We focus on long-term partnerships that help buyers reduce risk and maximize value.

Source High-Performance Wear Plates Today

If your operations demand reliable abrasion protection and long-term cost control, wear-resistant steel is the right investment. Strengthen your supply chain by partnering with a trusted and buyer-focused supplier.

Vandan Steel & Engg.co

359 / 373, Flat -9, 2nd Floor, Minerva Mansion, Svp. Road, Khetwadi, Giragoan, Mumbai -400004.

???? +91-8828813630

✉️ [email protected]

Contact us today to discuss your requirements and receive a competitive quote for high-quality Wear Plates tailored to your application needs.